This coating is highly resistant to weather conditions and ageing processes, thanks to which the elements retain their shine and aesthetic appearance for a long time. In the case of brass and copper substrates, we use additional chemical surface polishing to improve the quality of the finish.

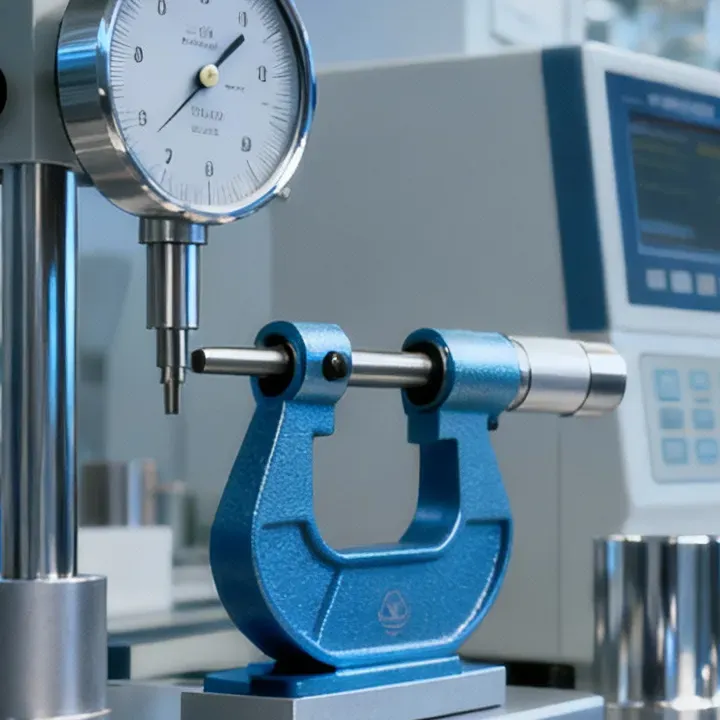

Our electrolytic chromium plating technology is carried out using the rack method, which ensures even coverage and quality control of the chromium layer. Chromium plating is widely used on steel, chromium-nickel steel, copper and brass, offering protection for these metals with a decorative effect. The process is used for components that require both high durability and aesthetics, including automotive and industrial components as well as decorative elements. The use of Surtec technology guarantees the highest quality of the coating and its compliance with industrial requirements.