Advanced technologies require equally modern control and analytical facilities. Since 2004, Galwano-Perfekt has been operating a laboratory that allows for detailed testing, control and certification of the services provided. Thanks to continuous development and investment in equipment, our laboratory is now one of the best-equipped facilities in the region.

The main tasks of the laboratory include:

- performing routine analyses and measurements of coating parameters,

- interpreting results and preparing reports,

- implementing new testing methods,

- providing analytical services for external companies and institutions.

Our laboratory performs, among other things:

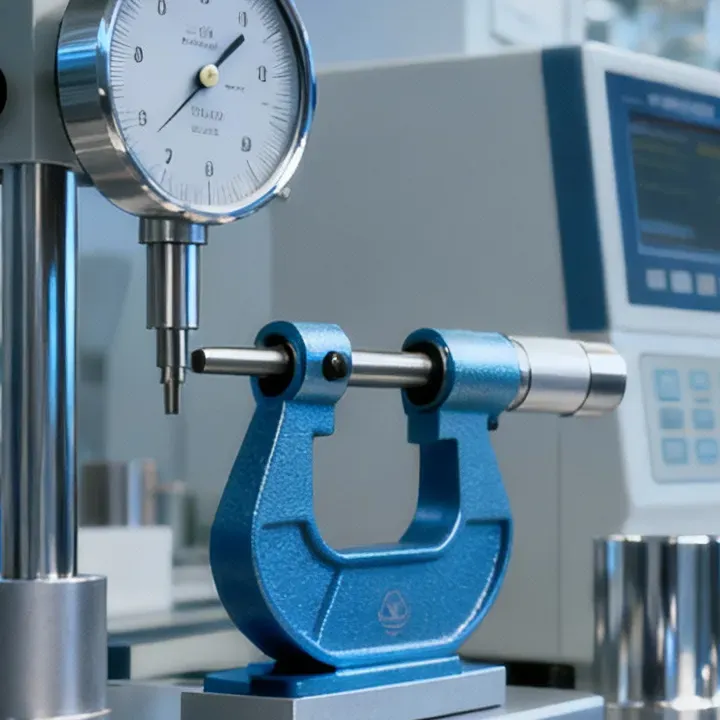

- measurements of the thickness of galvanic coatings (including X-ray, induction and eddy current methods),

- microhardness measurements,

- heavy metal content analyses,

- water and wastewater quality testing using ion chromatography,

- corrosion testing in a salt chamber,

- advanced analyses of colour, gloss and other surface parameters.

The equipment includes, among other things:

- Jasco UV-VIS spectrophotometer,

- Fischerscope X-RAY X-ray fluorescence spectrometer,

- Solar M5 Thermo atomic absorption spectrometer,

- Metrohm ion chromatograph,

- Weiss Umwelttechnik GmbH salt chamber,

- Byk-Spectra colour analysis chamber,

- Colour-Guide spectrocolorimeter,

- micro-Tree-Gloss,

- Anotest system,

- HM 2000 S,

- ISO-Scope,

- Delta-Scope,

- Sartorius analytical balance.

Although the laboratory is not accredited, it operates according to standards equivalent to those of accredited laboratories and meets their requirements, which guarantees the reliability and validity of the results it issues.