During chemical nickel plating, components are immersed in a special autocatalytic bath, where a specific chemical reaction leads to the deposition of a nickel alloy containing phosphorus. The coating of this alloy has different mechanical properties depending on the phosphorus content, where low-phosphorus nickel plating is characterised by hardness and strength, and high-phosphorus nickel plating is characterised by excellent corrosion resistance and antistatic and non-magnetic properties. It is also possible to use Teflon-reinforced nickel coatings, which increase abrasion resistance and improve tribological properties.

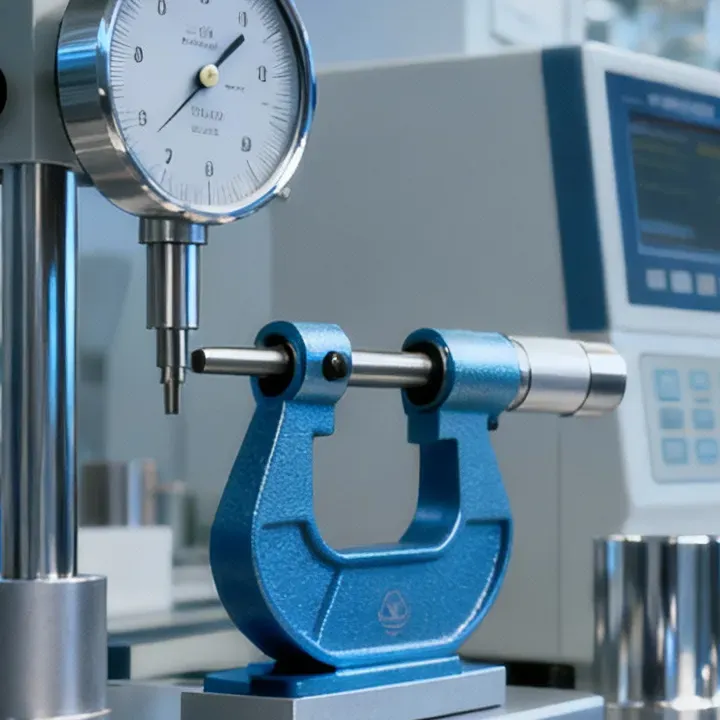

The parameters of the chemical coating are strictly controlled, including abrasion resistance, hardness, internal stress, tensile strength and corrosion resistance, tested in accordance with DIN standards. The process is mainly used in the rack method, with a barrel option for small components, on modern, mechanised lines with a load capacity of up to 300 kg.