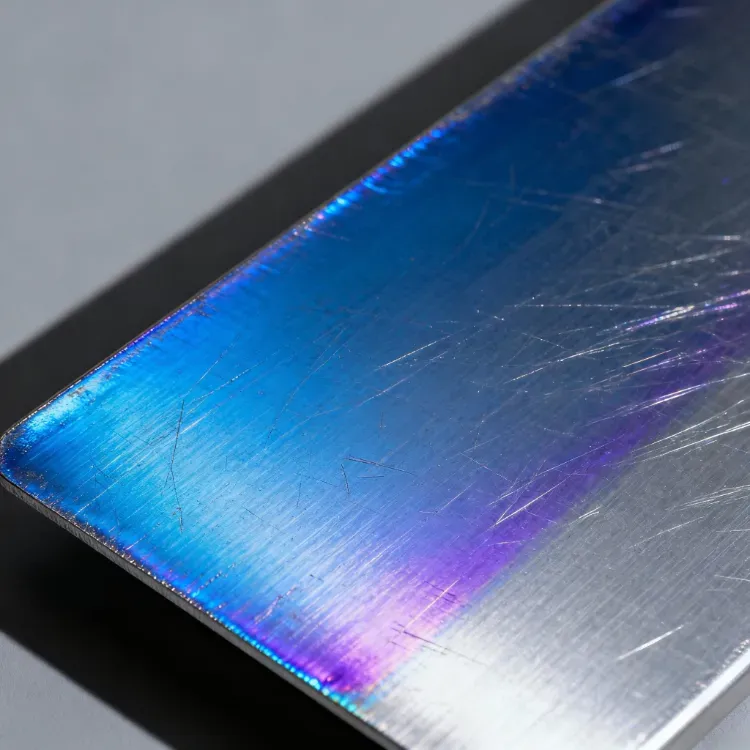

Chromium plating creates a passive protective layer that effectively protects aluminium against aggressive atmospheric, chemical and mechanical factors. The iridescent coating we offer takes on a characteristic blue hue, and thanks to the use of hexavalent chromium-free preparations, it meets the current requirements of RoHS 2, WEEE and ELV standards, making the process environmentally safe and compliant with EU regulations.

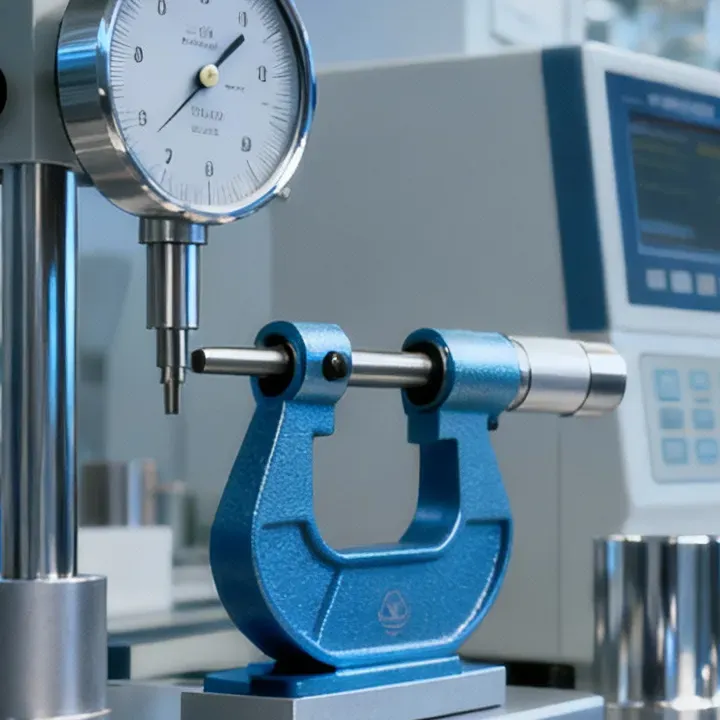

The chromate coating provides excellent corrosion protection – it meets the requirements of MIL-DTL-81706B and MIL-DTL-5541F standards, confirmed by a 336-hour neutral salt spray (NSS) resistance test. It can be used as a passivation for magnesium alloys and as a sealant for coatings after anodising. In addition, it has high thermal resistance and is ideal for preparing surfaces before painting or bonding.