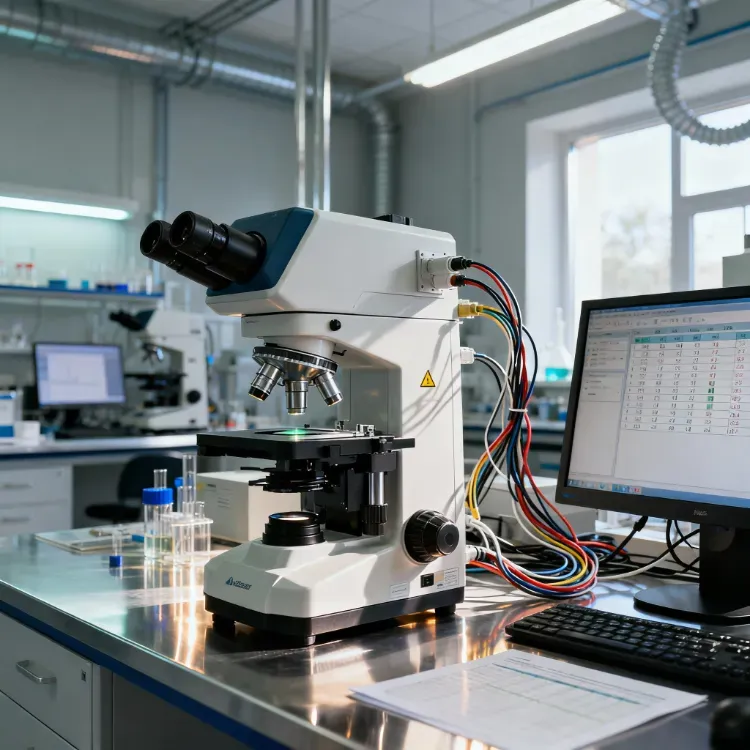

In our in-house laboratory, we offer professional and comprehensive testing services dedicated to the electroplating industry and specialist industries. Thanks to our advanced technical facilities and experienced team of experts, we carry out a wide range of analyses and measurements that allow us to monitor and ensure the highest quality of electroplated coatings and product functionality.

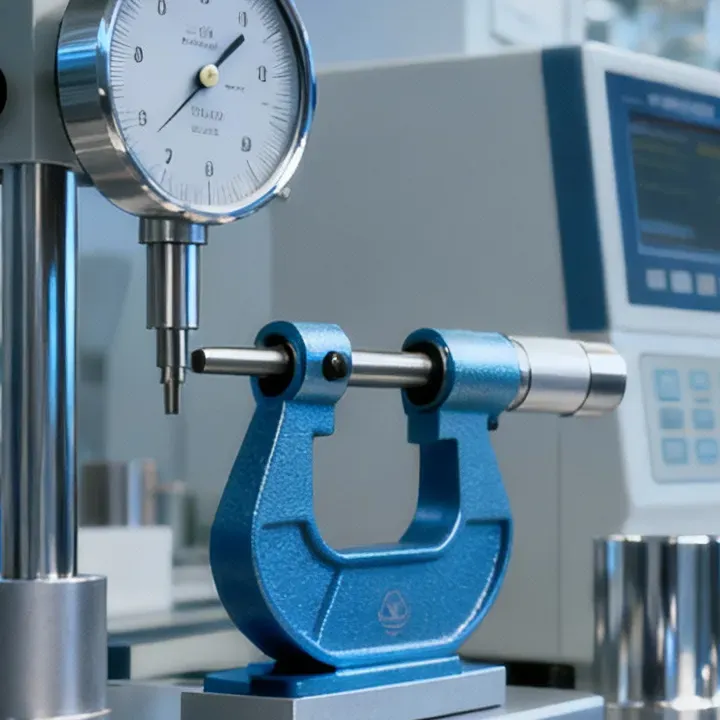

We perform precise measurements of coating thickness and microhardness, analyse the presence of heavy metals in samples, and conduct detailed water and wastewater quality tests using modern ion chromatography methods. We also perform corrosion tests in neutral salt spray, which allow us to assess the durability of coatings in environmental conditions.

In addition, we perform analyses of galvanic baths, assess the degree of coating mattness and conduct colour spectrum tests for aesthetic and quality standards. We are also able to assess the effectiveness of anodic coating sealing, which is crucial for their durability and protective properties.

We tailor our services to individual customer requirements, providing reliable reports and technical support at every stage of order fulfilment. We ensure the highest standards of compliance with industry norms and standards, making us a reliable partner in the process of quality control and product development.